Application Case

01

Intake Filter Filtering Colloid Fitted on H150 Rotary Piston Pump

A enterprise of carbon products, had a problem of carbon powder and the slurry were easily sucked into the H150 rotary piston pump they used. It would damage the vacuum pump. However, using LVGE intake assembly, the problem was solved. Besides, the enterprise also installed LVGE exhaust filter to purified the exhaust discharged by the pump.

02

Inlet Filter Filtering Acid Gases Applied in the Food Industry

A food processing enterprise produced lactic acid bacteria. During the production, there would be acidic gas corroding the vacuum pump. But LVGE inlet filter successfully helped the enterprise solve it.

03

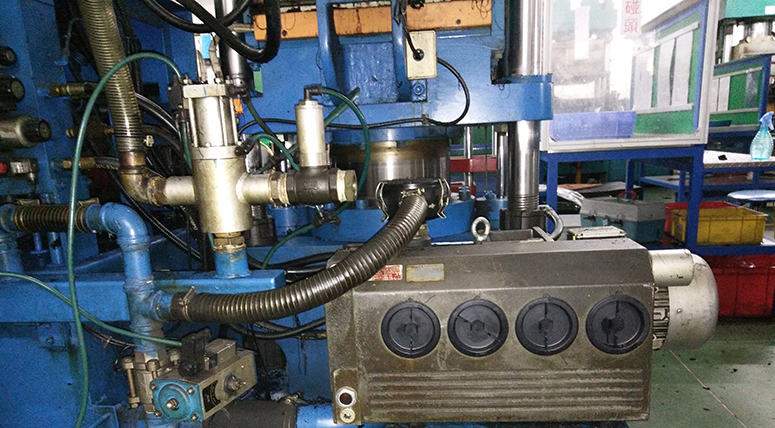

Gas-liquid Separator Applied in the Lithium Cell Industry

A lithium cell enterprise used LVGE gas-liquid separator to effectively prevent the electrolyte from being sucked into the vacuum pump provided with the injection machine.

04

Oil Mist Filters Fitted on 2X-70 Two-Stage Rotary Vane Pump in the Photovoltaic Industry

A customer in the photovoltaic industry was producing solar panels. In order to filter oil mist, he bought oil mist filters from LVGE for his laminators fitted with 2X-70 two-stage rotary vane pump. And LVGE filters did it.

05

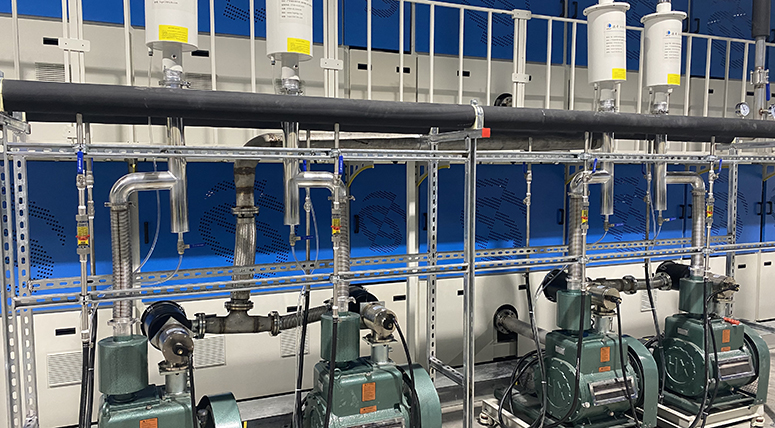

Exhaust Filters and Inlet Filters Fitted on Single-Stage Rotary Vane Pumps

A negative pressure pump station of an electronic factory adopted 300m³/h vacuum pumps. It replaced the original filters with LVGE filters, and greatly reduced the maintenance cost of vacuum pumps.

06

LVGE Oil Mist Separators Fitted on Becker Vacuum Pumps

LVGE oil mist separators were fitted on Baker vacuum pumps used in the printing industry. And the customer was very satisfied with the effect.

07

Oil Mist Separators Fitted on Elmo Rietschle VC100 Vacuum Pumps in the Rubber Industry

LVGE’s alternative filters for the original ones of the VC100 vacuum pumps, were applied to a rubber vulcanizing press. As a result, they were not only easy to install and perfectly matched the machine, but also had a excellent filtration efficiency!

08

Oil Mist Filters Fitted on H150 Rotary Piston Pumps in Single-Crystal Silicon Industry

A company in the photovoltaic industry got good filtration efficiency and saved 5 liters of vacuum pump oil per furnace produced, using an LVGE oil mist filters for its H150 rotary piston pump provided with the single crystal furnace.

09

Oil Mist Separators Fitted on H150 Rotary Piston Pumps in Vacuum Heat Treatment

A vacuum heat treatment manufacturer equipped LVGE oil mist separators for all H150 rotary piston pumps in the workshop. Equipped with the filters, the pumps could even directly emit gas indoors without pollution.

10

LVGE Oil Mist Filter Fitted on Vacuum Furnace

A vacuum furnace manufacturer adopted LVGE oil mist filter. And a engineer confirmed that there was no smoke visible, and was satisfied with the result of filtration efficiency test.

11

Oil Mist Separators Fitted on H150 Rotary Piston Pumps in the Glass Coating Industry

A glass coating enterprise had been plagued by the fume of vacuum pumps. After using LVGE oil mist filters, it not only solved the trouble but also saved a lot of vacuum pump oil.

12

LVGE Filters Fitted on Busch RA0160D Vacuum Pumps in the PCB Industry

The replacements of 0532140159/0532000004 filters were fitted on Busch RA0160D vacuum pumps applied in the PCB industry. There was no smoke and oil coming out in the long-term service life of the filters.

13

LVGE Filters Fitted on Elmo Rietschle VC303 Vacuum Pumps in the Food Packaging Industry

A food factory that produced tuber mustard had equipped its vacuum pumps with the replacements of 731630-0000 filters. The factory was concerned that impurities such as salt and oil would corrode the filters. But it has been proven that LVGE filters had good corrosion resistance and could still operate well for a long time under such harsh operating condition.

14

Exhaust Filters Fitted on 2X-70 Two-Stage Rotary Vane Pump in the Titanium Coating Industry

To purify the emissions of vacuum pumps, a company in the titanium coating industry, applied LVGE exhaust filters to 2X-70 two-stage rotary vane pumps .

15

Oil Mist Separators Fitted on Leybold SV300B Vacuum Pumps in the Electronics Industry

An electronic factory fitted replacements of 971431120 oil mist separators and replacements of F006 intake filters on Leybold SV300B vacuum pumps.

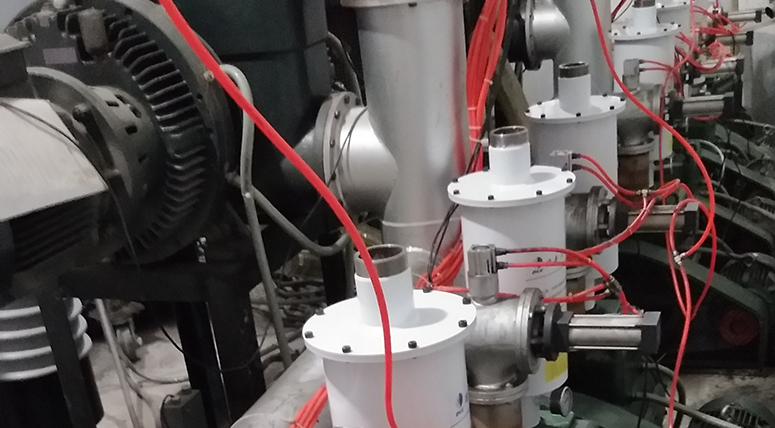

16

LVGE Intake Filters Fitted on Dry Screw Vacuum Pumps in the Semiconductor Industry

The LVGE intake assembly could be applied on the dry screw vacuum pump. Its excellent tightness and high filtration efficiency fully met the requirements of the semiconductor industry.

17

The Replacements of Original Filters Fitted on Busch RA0302D Vacuum Pumps in the Lithium Cell Industry.

LVGE exhaust filters were fitted on Busch RA0302D vacuum pumps applied in the lithium cell industry.